Secondary Battery Equipment

Sejong Technology produces secondary battery manufacturing equipment and display equipment, which are the industry of the future. With over 10 years of experience and know-how, we continue to research and develop to prepare for the future. We will always try to offer the best technology and equipment manufacturing technology.

Prismatic Cell

Cylindrical Cell

Pouch Type

Module Line

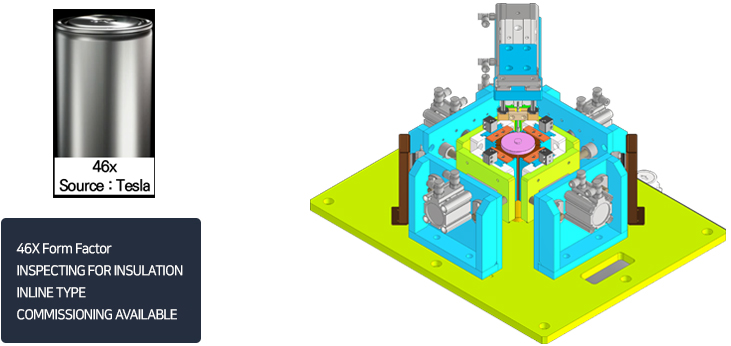

INSPECTING INSULATION OF CYLINDRICAL SECONDARY BATTERY

BATTERY

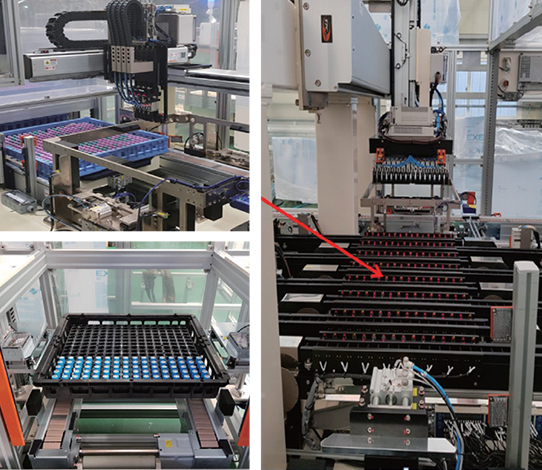

Grading & NG sorter MC

Tray Load

NG Cell Sort

A Grade

B Grade

C Grade

C Grade

Tray Merge

Tray Unload

BATTERY

EQ Picture

| Production Type | 18650, 21700 |

|---|---|

| Production CAPA | 300PPM |

| Equipment Size | 40m x 10m x 2m(H) |

| Equipment Size | 4Axis robot |

| Tray Protection | Cell Chuck Type |

| J / C Type | Automatic |

| Control Type | PLC+PC |

| Machine Efficiency | 98%↑ |

| OK Rate | 99%↑ |

| Pneumatic | 6Kg / cm² |

| Power | 3 phase 220V |

| Production Delivery | 5 Months |

※ Note : Possible to manufacture on customer spec requirement.

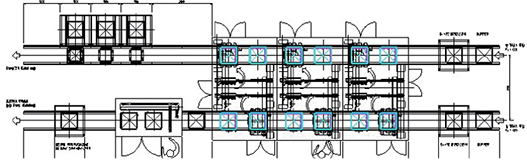

Vision Inspection

BATTERY

| Product Application | Cylindrical Cell(18600, 21700) |

|---|---|

| Main Function | Area : Top, Bottom, Sides Inspection List : Dent, Scratch, Contamination, Foreign Sub-stance |

| Sales Record | Samsung SDI |

| Samsung SDI | 18650, 21700 |

| Production CAPA | 330PPM |

| Equipment Size | 12m x 6m x 2m(H) |

| Cell Transfer | Pocket Converyor |

| Cell Protection | Coated Gripper |

| J / C Type | Automatic |

| Automatic | PLC + PC |

| Machine Efficiency | Over 95% |

| Reliability | Over 99% |

| Pneumatic | 5.5Kg / cm² |

| Pneumatic | 3상 220V 60Kw |

| Production Delivery | 4 Months (Delivery Basis) |

※ Note : Possible to manufacture on customer spec requirement.

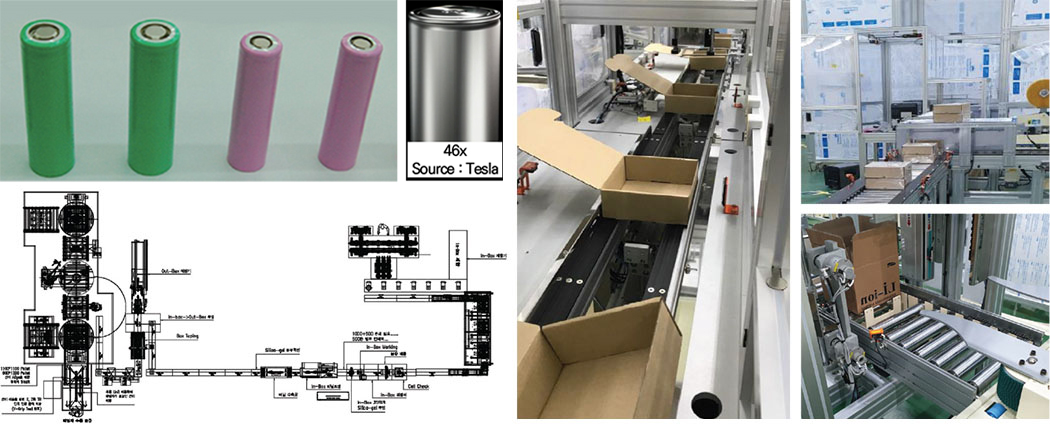

Cylindrical Cell Shipment Packaging Automation

In Box Fold

In BOX Slipsheet

Cell Load

Cell Check

Silica GelInsertion

Vinyl

OUT BOX Fold

BOX Taping

Outbound Pallet

BATTERY

| Product Application | Cylindrical Cell / Polymer Cell |

|---|---|

| Main Function | Automated Delivery Packaging 18650 : Corrugated cardboard 21700 : PP Tray |

| Sales Record | Samsung SD |

| Production Type | 18650, 21700 |

| Production CAPA | 330PPM |

| Equipment Size | 20m x 12m x 2.5m(H) |

| Cell Transfer | Suspension Bridge |

| Cell Protection | Coated Gripper |

| J / C Type | Automatic |

| Control Type | PLC + PC |

| Machine Efficiency | Over 95% |

| Reliability | Over 99% |

| Pneumatic | 5.5Kg / cm² |

| Power | 3 phase 220V 80Kw |

| Production Delivery | 4 Months (Delivery Basis) |

※ Note : Possible to manufacture on customer spec requirement.